Single Jacket ADSS Cable

Product Show/ PRODUCT

Copyrights Reserved

Product description/ PRODUCT

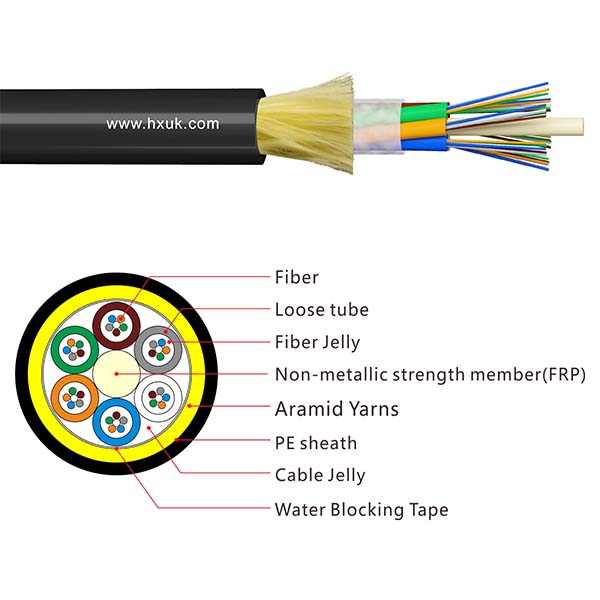

ADSS cable adopts the twisted structure. 250μm fiber is inserted into the loose tube made of high modulus materials. The tubes are filled with a water-resistant filling compound. The tubes (and fillers) are stranded around a FRP (Fiber Reinforced Plastic) as a non-metallic central strength member into a compact and circular cable core.The gap of the cable core is filled with a water-blocking yarn and a water-blocking tape longitudinally wrapped by the cable core. After stranded layer of aramid yarn are applied as strength member, the cable is completed with PE or AT (anti-tracking) outer sheath.

Product Picture/ PRODUCT

Product Features / PRODUCT

·Can be installed without shutting off the power

·Adopt AT performance, excellent dielectric performance

·Light weight and small diameter reducing the load caused by ice and wind and the load on towers

·Good performance of tensile strength and temperature

·The design life span is 30 years

Product Application / PRODUCT

·The actual status of overhead power lines is taken into full consideration when ADSS cable is being designed. For overhead power lines 10kv and 35kv, PE outer sheath is applied.

·FOR power lines 110kV and 220KV, AT outer sheath is applied.

·The dedicate design of aramid quantity and stranding process can satisfy the demand on various spans.

Product Standards / PRODUCT

The ADSS cable follows the IEEE P 1222 technical standard, and meets the IEC 60794-1 standard and DLT 788-2016 standard.

Optical Characteristics/ PRODUCT

|

|

|

G.652 |

G.655 |

50/125μm |

62.5/125μm |

|

Attenuation |

@850nm |

- |

- |

≤3.5dB/km |

≤3.5dB/km |

|

@1300nm |

- |

- |

≤1.5dB/km |

≤1.5dB/km |

|

|

@1310nm |

≤0.45dB/km |

≤0.45dB/km |

- |

- |

|

|

@1550nm |

≤0.30dB/km |

≤0.30dB/km |

- |

- |

|

|

|

@850 |

- |

- |

≥500MHZ·km |

≥200MHZ·km |

|

Bandwidth |

@1300 |

- |

- |

≥1000MHZ·km |

≥600MHZ·km |

|

Numerical aperture |

- |

- |

- |

0.200±0.015NA |

0.275±0.015NA |

|

Cable Cutoff Wavelength |

- |

≤1260nm |

≤1480nm |

- |

- |

Technical Parameters/ PRODUCT

|

Cable Diameter |

Cable Weight |

Recommend maximum working tension |

Maximum allowable working tension |

breaking tenacity |

Section area of tensile components |

modulus of elasticity |

thermal expansion coefficient ×10-6 /k |

|

|

PE sheath |

AT sheath |

|||||||

|

9.8 |

121 |

130 |

1.5 |

4 |

10 |

4.6 |

7.6 |

1.8 |

|

10.2 |

129 |

138 |

2.1 |

5 |

14 |

6.9 |

8.1 |

1.4 |

|

13.1 |

132 |

143 |

2.8 |

7 |

19 |

9.97 |

9.13 |

1.2 |

|

15.6 |

189 |

207 |

3.8 |

9 |

26 |

14.2 |

11.2 |

1.0 |

Storage/Operating Temperature : -40℃ to + 70℃

Customer evaluation/ PRODUCT

|

M

Martin |

German |

|

M

Mac Donald |

Dublin reland |

|

A

Alexander |

United Kingdom |

|

G

Gabin |

France |

|

W

William Dinh |

Canada |

|

A

Ahern |

United Kingdom |

|

A

Anthony Italy |

Italy |

|

S

Semele |

United States |

|

C

Carlos |

Brazil |

|

G

Ginette |

Spain |